Additive technology allows for complete dimensional freedom of PTMS designs

Sintavia designs PTMS components using state-of-the-art CFD simulation software combined with proprietary additive material and process technology. The resulting components are better performing, less expensive, and more easily manufactured than traditional PTMS components.

Have any questions?

Get in touch with one of our specialists.

Sintavia works with its customers to identify the right parameters that will allow for the quality, high-speed production of components and systems

With unparalleled on-site capabilities—including design, powder analysis, printer correlation, CT scanning, metallurgical analysis, and mechanical testing—Sintavia is the global leader for additively-enabled Power & Thermal Management Systems.

Sintavia’s Approach – Controlled Process to Production Quality

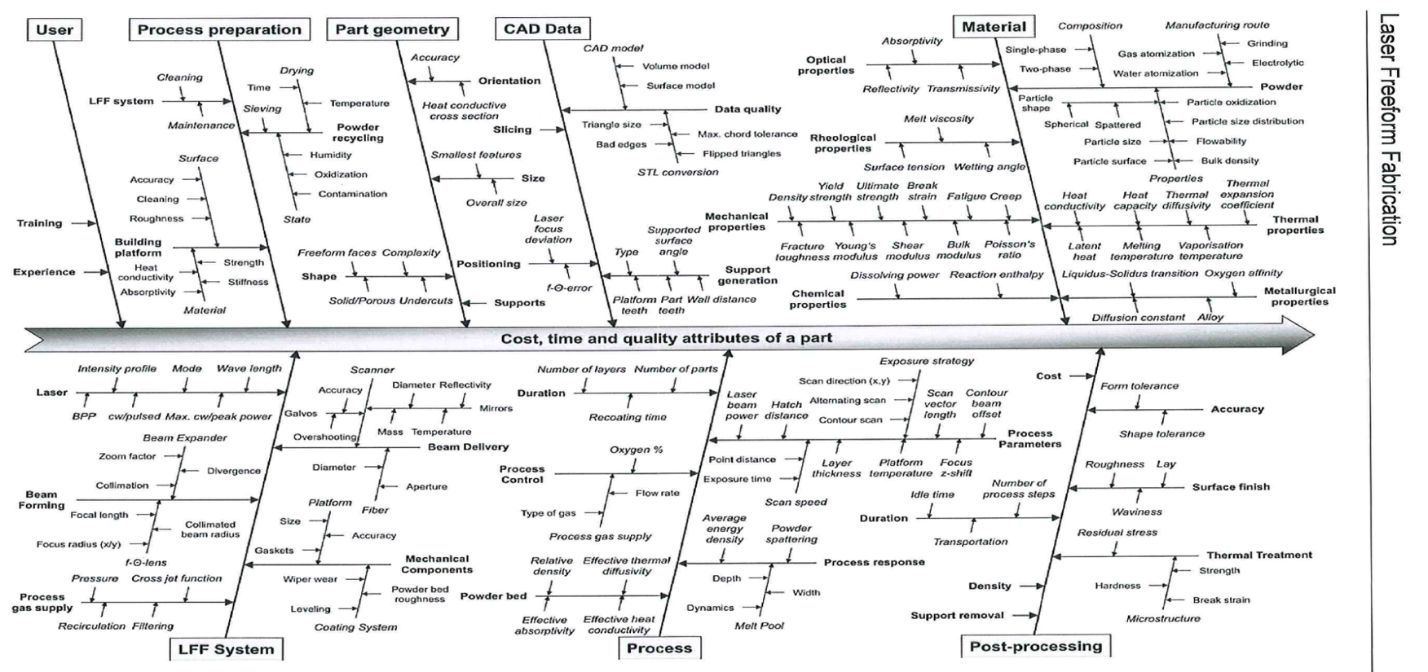

Optimizing and controlling parameters for the AM process is a difficult task given the numerous parameters involved throughout the entire program. Sintavia has been able to demonstrate to its customers that its in-house vertically integrated approach results in better designed and additively manufactured components.

CASE STUDIES

Advantages of AM

These designs can offer substantial weight savings and performance in modern aerospace advanced system and assembly design. Each design is manufactured from electronic data generated from CAD files making it a fully direct digital manufacturing process.

Since the design is controlled directly from a CAD file, AM can produce parts that were at one time impossible to manufacture by conventional processes such as cutting, grinding and drilling.

The design is only limited by a designer’s creative abilities. Features such as conformal cooling inserts, functional integration, complex geometries, lattice networks and hollow members are now produced with considerable ease via the AM process.

Since it is all accomplished in an additive fashion instead of a subtractive fashion, AM offers reduced material waste and lower life cycle energy use while offering highly sustainable designs.